Restoration Process

Disassembly & Stripping

New paint going on is only as good as what is underneath it. With that being said it is important to do things the right way, the first time around as to avoid problems in the vehicle's finish early on. Stripping the exterior to bare metal and starting from a good foundation is key. The engine, transmission, suspension, brakes, all of the body parts and trim are removed. The paint is ground down to an 80 grit scratch, seam sealer such as along the drip rails is wire wheeled out, and glass is removed to coat the lip it rests on. The vehicle body is mounted to a rotisserie to easily address all areas needed.

The restoration process begins with a few important goals. One, to bring to fruition your dream car whether that's restoring that particular vehicle back to it original like-new condition, or by working together to add in some modern mechanical changes, and/or designing custom visual alterations to the exterior and interior to suit to your own unique style. Secondly, I strive to make the process a pleasant experience. Patience is needed, especially for being a one-man operation, but I like to fill those gaps with picture texts/ email updates, and welcoming phone calls or casual, fair notice, appointments to stop by the shop and see the work in progress and in person. Bottled water and soft drinks are always stocked in the office refrigerator, hot coffee, and light snacks. Bring a friend, your family or just yourself and make yourself at home.

Once we have come to agreement on the concept and timelines, we're ready to get to work. Comprised below are general elements from beginning to end.

Epoxy and Body work

The next stage after stripping down to bare metal is protecting the surface in a corrosive resistance coating that is direct to substrate, this is an epoxy hybrid that also acts as a high build surfacer which can be applied over body filler where needed. It offers excellent adhesion and durability. Rusted areas are cut out and new panels welded in where necessary. The underbody is coated and inside of the frame rails for rust prevention. The body is block sanded by hand with a guide coat.

It's off to the paint booth once primer is block sanded and masked off. State-of-the-art refinishing equipment and high-quality paint is used. New booth filters are used on all major restorations to minimize containments from entering the booth. Optionally, a flow coat can be applied which adds two extra layers of clear for added depth and rock chip protection. There are over 100 unique speed shaped color samples in shop to check out, and if you still don't see the right one, a spray out can be made for what you do have in mind.

Also known as color sanding, is the process of sanding down the finish in stages from 1500 grit, to 2000, then to 3000 before then buffing in 3 stages to a brilliant shine with little to no orange peel, which is the natural texture produced from spraying. Wet sanding will take a nice paintjob to an exceptional one.

New or restored parts are then installed using all new weatherstripping, nuts and bolts. Threads throughout the body are tapped clean where necessary and thread locker used appropriately. Torquing to OEM specifications and properly aligning panels with acceptable gaps.

Paint / Refinishing

Wet sanding and Buffing

Trimming / Assembly

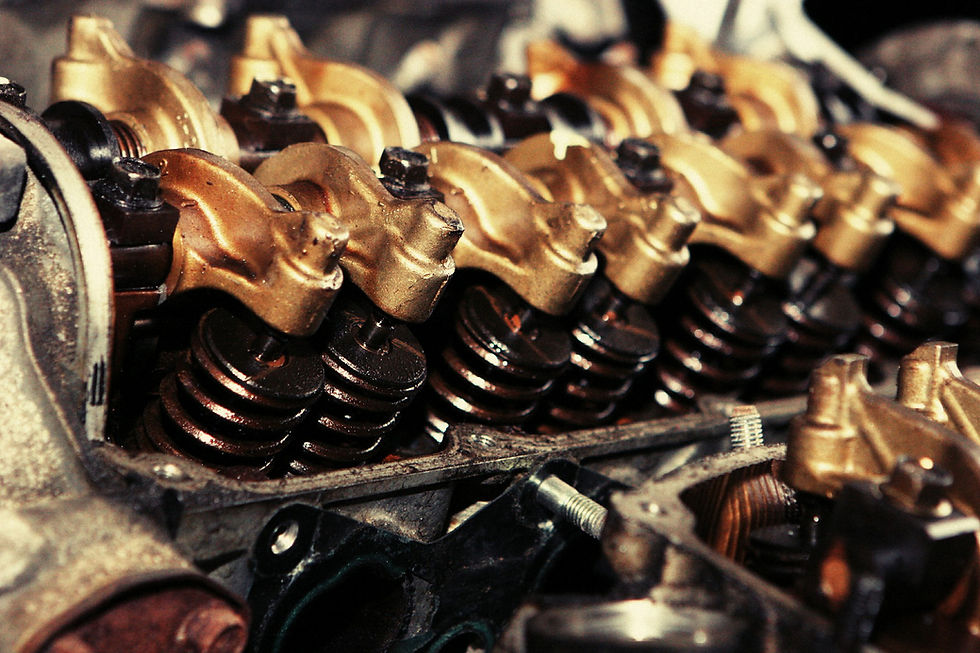

Engine Rebuild

Running or not, if doing a full frame-off rotisserie restoration it is suggested to rebuild for performance, reliability, and for overall uniformity of the complete restoration. This also is a less time-consuming part of the build (depending on machine shop backlog). The engine is completely disassembled, honed or bored/sleeved depending on cylinder condition. New bearings, freeze plugs, pistons, rings, timing chain/belt, and gaskets are installed. A compression test is performed, and a break-in done following the original manufacturers service procedures. The engine can also be painted in any custom color desired, aluminum polished and custom engraving to dress things up.

When it comes to the interior there are many options. Kits are often available that replace worn carpet, upholstery and trim. Pre-cut foam cushions and seat covers are easiest to install and most affordable. However, for one-off custom interiors its best to start from a clean slate. There is a large selection of sample leathers, suedes, vinyl, and stitching colors and sizes to readily pick from in shop. Custom dashes, consoles, seats and door panels can be first rendered digitally or drawn followed by sculpting a full-size rendition of what the end product will look like. This mockup is used to create a negative mold which will then be recreated in either fiberglass or carbon fiber. Lighting is addressed in these custom works to dial in the perfect ambience.

Dynamat, Kilmat, Stinger and a few other brands that offer rubberized sound insulation dramatically reduce road noise and vibrations while providing better listening while driving. A custom subwoofer enclosure can be made and hidden under or behind the seats, or inside the interior panels. Navigation screens to aftermarket replacement radios such as Retrosound that retain the original classic look but have built in auxiliary inputs bluetooth mic, and amplifier. As well, a new wiring harness, front to back, is always suggested when doing a full restoration.

Nothing beats a one-off, this is where you can let your imagination run wild. Customization/ fabricating is open at any stage of the build. It can be truly custom designed bumpers, hood, or other exterior body panels, interior trim pieces, or welding up suspension and brake upgrades. Airbrushing and pinstriping is another custom approach if desired. For more examples of this please give the 'Art' page of this site a look through.

Interior

Audio & Wiring

Custom Fabrication & Airbrushing

Final Inspection & Detailing

At this point the car is nearing its completion, but there is a checklist of things gone through to ensure everything on the vehicle is tight and right. Test drives after a major restoration is mandatory before delivery. A couple hundred miles of driving is performed to again ensure the safety and smooth drivability. Once this passes inspection the vehicle is then thoroughly detailed inside and out, and atlas it is prepped for its reveal day!

%20resize_edited_edited_jp.jpg)